In the medical device manufacturing industry, where high quality and precision are always required, keeping a stable supply of materials for production is critical.

As a Procurement Manager at a healthcare device company in British Columbia, Canada, I faced a situation that made me re-evaluate our entire sourcing strategy: the risk of stockouts for critical production materials because we were depending on only one supplier.

Classifying Materials: Critical vs. Non-Critical

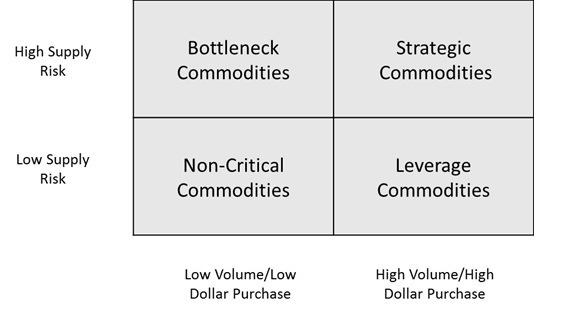

While reviewing data in our ERP system, I classified all production materials into two main groups:

-

Non-critical materials: common items that are easy to replace on the market, such as screws and general connectors.

-

Critical materials: items with specific technical requirements that are hard to replace — for example, custom machined components, special cable assemblies, and PCB boards.

For these critical materials, even a small issue with a supplier can stop the entire production line, causing serious delays and affecting our customers.

The Problem: Relying on a Single Supplier (Single Sourcing strategy)

The risk became clear when one of our main suppliers started missing lead times and increasing prices without clear explanations.

Although this supplier had worked with us for a long time and was considered reliable, depending 100% on them created a major weakness in our supply chain. I realized that no supplier is truly “safe” if you only have one option.

The Solution: Building a Dual-Sourcing Model

I proposed and implemented a Dual-Sourcing strategy for critical materials where it was possible. The idea was to develop two suppliers in parallel for each critical item:

-

A local supplier (in Canada or the US), who could provide faster delivery, quick support, and stronger responsiveness.

-

An international supplier (in Vietnam or China), who could offer better pricing and was suitable for large or long-term orders.

Finding and evaluating a second supplier was not easy. I worked closely with our engineering and quality teams to develop a clear evaluation process.

We looked at production capacity, international certifications such as ISO 13485, and the ability to meet RoHS standards since our products are also sold in the EU. We also checked if the supplier could handle technical customizations and deliver on time.

After choosing the second supplier, I set up a trial period for each one, testing their product quality, monitoring their process, and only fully onboarding them when the results were stable.

The Result: A More Flexible and Resilient Supply Chain

After a few months, our supply chain became much more flexible and proactive.

When we needed materials urgently, we could rely on the local supplier. For long-term projects with cost-saving goals, we ordered from our Asian partners. Most importantly, we were no longer stuck if one supplier had a problem.

If another global event like COVID ever happens again — with sea freight costs tripling and container shortages — we can still keep production running thanks to our local supplier. This is clear proof that the dual-sourcing model works.

From this experience, I learned that:

Even the most reliable supplier can still be a risk if you have no backup.

Dual-sourcing not only helps reduce the risk of stockouts, but also gives you stronger negotiation power, better sustainability, and faster response across your supply chain. It’s a strategy that every buyer, planner, or supply chain manager should consider when planning for long-term supply stability.

huyhtjzmng

grqvorlrystpnekfsmeguznjkozppe

smpfxoemxd

lvvdftruziozfniswtztjrluvzpkuy